Product Brand:

Product Model:

Views:3485

1, the project background

Detection of the appearance quality of cigarette packet packaging, cigarette production process is to ensure that an important means of quality. Because of the cigarette packet packing quality detector can only detect the traditional 5 surface, the sixth surface [Close] side of the conveyor belt is not detected, it is difficult to avoid [sixth] packing surface undetected defect condition. Small single appearance detection system this system developed for the detection of cigarette packet sixth faces.

2, solutions

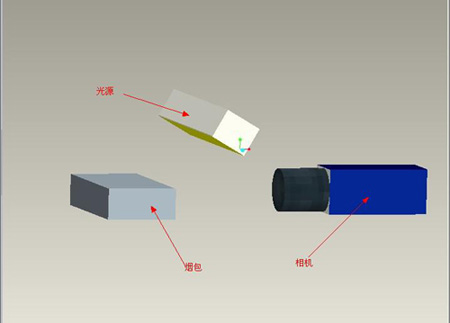

Composed of 2.1 system: mainly consists of image acquisition module, image processing unit and a control execution unit of three parts. Image acquisition system consists of image acquisition card, CCD camera, light industry, industrial control computer as the image processing unit, the processing result as the control execution unit.

2.2 working principle: the steady field conditions, industrial cameras capture every packets through the collection area cigarette image, by bus to transfer data to the computer, the data processing by the image processing software for a specific, treatment results from the GPIO interface output IPC to cigarette packaging machine, by eliminating mechanism packaging machine for eliminating mechanism [] by pulse deposit is a bit detection to remove separated by many packs of cigarettes as a pulse.

2.3 system features:

2.3.1 light source: the combination of light source intensity LED customization

The 2.3.2 camera: using high speed industrial camera frame rate up to 60fps

2.3.3 processing software: friendly interface, rich algorithm

2.3.4 IPC: no fan duo host computer

2.3.5 display: the converter to achieve PC share a display two sets (such as OPC display can achieve the function of circumstances)

The key technology and properties of 2.4 products

2.4.1 detection system in long-term operation does not need maintenance parameters detection system for the detection area after setting, will not require maintenance, replacement of grades is simply switch.

2.4.2 uses a special light source, image without any spot, can detect the details of each device adopts special shadowless light, ensure the imaging appearance of special cigarette packet is clear, without spot, and guaranteeing the detection precision.

2.4.3 system to realize the network function, a host monitor packet detection equipment host all through the network, dynamic display of wealth of statistical data, at the same time the faulty equipment can realize network debugging, no longer need to each site for inspection and debugging, and if the site equipment problems, the operator can notify the host network monitoring inspection and testing.

2.5 performance index:

Hard box side seal is opened, become warped edge detection rate ≥ 99 false detection rate ≤ 0.3 ‰

Hard box, bag hanging rotten rate ≥ 99 false detection rate ≤ 0.3 ‰

Soft packaging dislocation rate ≥ 99.9 false detection rate ≤ 0.1 ‰

The soft packing dirt detection rate ≥ 98 false detection rate ≤ 0.3 ‰

2.6 removing method

Because of the installation position and space constraints, excluding only by internal rejection mechanism of GD packaging machine.

Fig. 3 Schematic, installation mode and effect

Schematic diagram of system

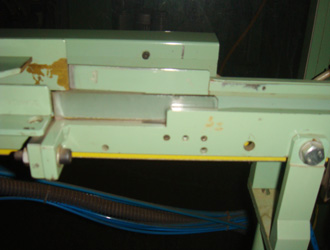

Installation position (1)

Installation: baffle the arrow refers to remove and install the detection system, can be used to detect a packet of sixth.

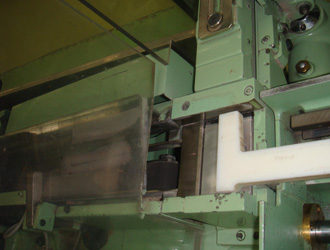

Installation position (2)

Installation: detection system installed in the suction cup runner, arrow is the detection work, the packet sixth face detection here.

Installation position (3)

Installation: detection system is installed in the rod of the cigarette package to promote the conveyor belt, the detection work of putt just promote the position of the conveyer belt, camera for strabismus packet sixth surface.

Installation position (4)

Installation: detection system installed in a single package conveyor belt, but the detection of words, conveying push plate belt would get in the way of sixth surface about 30%, there is interference on the detection of surface.

[various installation modes will be considered a variety of models to choose to install the appropriate way. ]

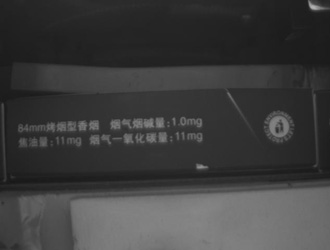

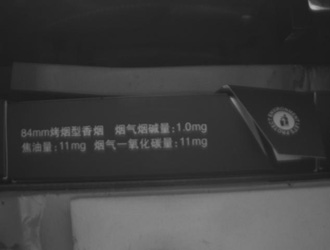

4, the imaging effect diagram (defects)

5, the product after sale service

Our company specialized in tobacco industry in a packet, packet machine vision inspection device has 5 years of history, a machine vision device installed in many factory our country, use effect has been unanimously recognized and praised the manufacturers. This product is a new generation of packet after sixth new development of long-term accumulation of our appearance inspection equipment. Professional and continuous improvement is our aim, to improve the tobacco industry is our honor utility and mature products.

Our company provides perfect after sale service for the use of factory. Also our company has been committed to improving the product, provide free product upgrading and transformation.